Ref. REDS MRO:PC214-00386

Previous.ref : PC214-00386

Ref.maker : I-644C5

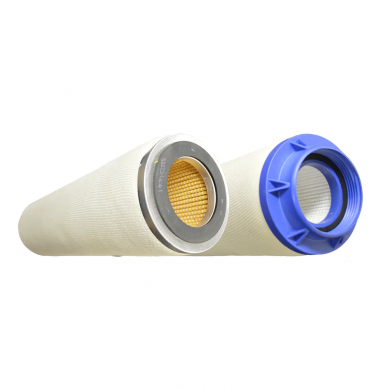

Coalescer cartridges are employed as the first stage in filter/separator vessels for hydrocarbon fluids. They perform two functions: (1) coalesce (combine) highly dispersed, emulsified water particles into larger water drops and (2) filter-out particulate contaminants.

VELCON I-644C5 Coalescer Cartridge — Technical Specifications

Filter Type: Coalescer

Certifications: Category C, EI1581

Application: Aviation

Gasket Material: Buna-N

Outer Shell: N/A

Filtration Rating (µm): 0.4 µm

Maximum Operating Temperature: 121.1 °C / 250 °F

Maximum Differential Pressure: 75 psi / 5.2 bar

Filter Media Construction: Fiberglass

Change-Out Differential Pressure: 15 psi / 1 bar

pH Range (Continuous Operation): 5 – 9

Brand: Velcon

Flow Rate: Varies depending on fluid viscosity and application. Refer to brochure for detailed specifications.

Application: Aviation

End Cap Configuration: Open End

Length (in): 44 inches

Inside Diameter (in): 3.500 inches

Outside Diameter (in): 6.000 inches

Coalescer Cartridges for Aviation and Industrial Applications

Coalescer cartridges are used as the first stage in filtration/separation vessels for hydrocarbon fluids. They serve two primary functions: (1) coalesce (combine) finely dispersed and emulsified water particles into larger water droplets, and (2) filter out particulate contaminants.

1) Product Features:

Cost-effective removal of particulates and emulsified water from hydrocarbon fluids

Easy installation and replacement due to one-piece design

Available in threaded base or open-end configurations

Choice of all-fiberglass media or a combination of fiberglass and pleated media

Proven field performance

Ongoing qualification testing to meet evolving commercial and military standards

Used as first-stage cartridges in filter/separators

Removes particulates and coalesces water into large water droplets

Also available with threaded base versions

2) Applications:

Coalescer cartridges are primarily used to coalesce emulsified water and remove particulates from hydrocarbons. The most critical application is jet fuel filtration. They are also employed for other fuels, refinery and petrochemical processing streams, and condensate streams in natural gas production.

Other immiscible liquids may also be separated if they have differing specific gravities and if high concentrations of surfactants are not present. As a general rule, if a sample of the mixture separates easily within one to two hours, a coalescer will likely be effective. If separation does not occur after 24 hours, coalescing is unlikely to succeed.

3) General Specifications:

Maximum differential pressure: 75 psi

pH range: 5 to 9

Maximum operating temperature: 150°-160°F

Aluminum center tube

Buna-N gaskets

Injection-molded end caps are standard on 6" diameter threaded base coalescers

Aluminum end caps are standard on 6" diameter open-end cartridges

All 6" diameter end caps are bonded directly to the media with high-strength epoxy or urethane adhesives

4" diameter cartridges are equipped with molded or injection-molded polyester resin end caps

The Energy Institute (EI) is now the governing body for aviation fuel filtration specifications. The American Petroleum Institute (API) is no longer involved in aviation fuel filtration standards.